Problem Statement

As sustainability has become an increasing focus in many aspects of our lives in recent years, construction industry professionals have been working to address sustainability concerns by finding ways to expand the use of renewable resources in the built environment. The challenge is to do this without increasing cost or construction schedules.

The Value of CLT in Structural Design

Cross-laminated timber (CLT) is a prefabricated solid wood panel made from gluing together layers of solid-sawn lumber—think a really big version of plywood. CLT panels can be two to 12 feet wide and up to 60 feet long and come in varying thicknesses from approximately three to 20 inches. They can be used for floors, roofs, and walls, and since beginning to be incorporated into U.S. design standards in 2015, are able to be utilized for structural purposes in many jurisdictions. ZFA has closely followed the evolution of this relatively new material over the past decade and has utilized CLT in both new and existing buildings because of its sustainability and other benefits.

Sustainability

When compared to traditional steel and concrete materials used for similar purposes, CLT is typically found to have a smaller environmental impact. CLT is made of wood, which is a renewable resource that is increasingly being sustainably grown and harvested. Additionally, for projects in North America, CLT is considered “local” as it is typically produced in relatively close proximity to project sites. Life Cycle Analysis (LCA) studies, used to quantify carbon use through the life cycle of a building, have demonstrated a lower carbon footprint of CLT as compared to steel or concrete, not only due to the lower energy typically required to create CLT but also because wood is a “carbon sink” that absorbs carbon before it is harvested.

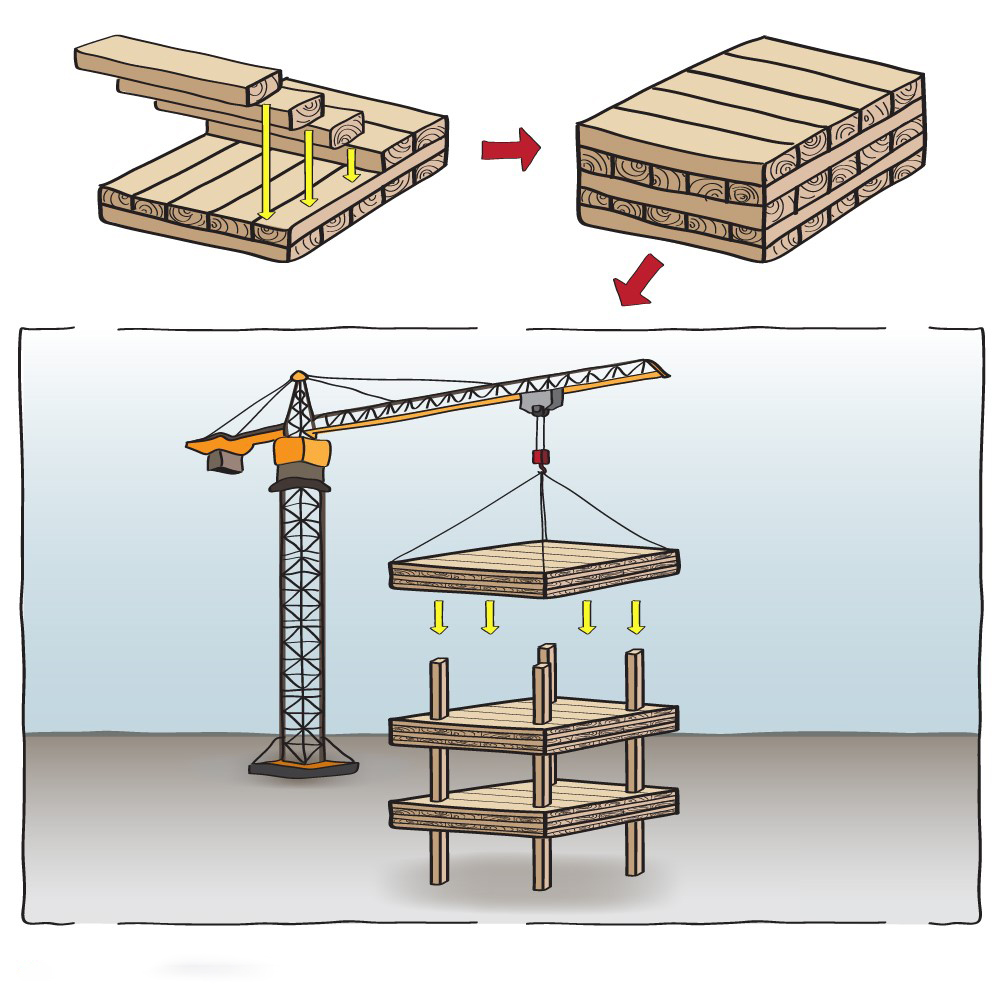

Faster Installation

Because CLT panels are premanufactured, they are typically installed like an erector set—large panels are craned into place and connectors quickly placed to tie the components together. Each panel typically takes the place of multiple, if not dozens, of framing elements that would be used in a typical wood- or steel-framed building, therefore reducing the time and labor it would usually take to install these separate components. Compared to a concrete building, there is no need for formwork, shoring, or reinforcement—once the CLT panel is in place and stabilized, the construction team can move to the next panel.

Lighter Buildings

Wood is a lighter material than steel or concrete, and while it does have lower strength, the use of wood as a solid, large-scale, premanufactured panel is often more efficient for floors and roofs. The weight of a typical CLT system is significantly less than a steel or concrete system, and when used over multiple stories, the weight reduction produces significant benefits for both the lateral force-resisting systems (in seismic regions) and foundation systems.

Seismic forces are based on a building’s mass—the heavier a building is, the more force it will feel due to an earthquake. Therefore, if the building is lighter, design earthquake forces will be smaller, and the materials used in a building to resist earthquakes will not be required to be as robust. Similarly, the foundations that support a building are designed to support the building’s weight—if the building is lighter, the foundations can be smaller, all of which saves cost.

The Result

CLT is an effective, efficient, and sustainable material being used in increasingly diverse building types around the U.S. and the world. While there still are many challenges with using CLT (e.g. code provisions not established for all uses/jurisdictions and limited production facilities), ZFA is committed to utilizing this material when appropriate to benefit our clients’ projects. Some examples of ZFA’s recent uses of CLT are below:

CLT Rocking Wall Design

ZFA got creative in its use of CLT on this new, 2,200 square-foot home in St. Helena, California that is a one- and two-story residential structure over a partial basement. The framing consists of cross-laminated timber (CLT) roof, parts of the floor, vaulted ceilings, and wall panels that form the gravity and lateral load-resisting systems.

ZFA designed a unique “rocking wall” system, which uses a steel cable tendon inside the CLT wall panel as a self-centering and seismic force-resisting device. The tendon is composed of one continuous cable that begins at the top of the CLT wall panel on one end, continues down through the center of the CLT panel and into the concrete wall below, then curves into a “U” shape to continue to the top of the other side of the CLT panel.

When earthquake forces parallel to the wall occur, the wall rocks, engaging the cable tendon as the wall tries to lift up on one side and using the cable elasticity to pull the wall back into its original position like a rubber band. This creative method was used to limit wall movement under seismic forces and protect the expansive windows in the home, which amounted to a sizable investment by the owner.

Historic Structure Reconstruction Incorporating CLT

In October 2017, the White Rock Winery in Napa, a wood and stone structure originally built in 1875 and listed on the Napa County Historic Resource Inventory, was largely destroyed by the devastating Atlas Fire. The original, thick, unreinforced stone walls were all that remained.

A thoughtful reconstruction was designed by ZFA to restore the structure while providing updated performance to meet current building code standards. CLT was used at the ceiling and raised ground floor to efficiently tie the stone walls together, providing a complete load path for lateral loads, and to improve head height in the lower level.

CLT Long-Span Roof at New Airport Terminal

When designing the new 30,000 square-foot expansion of the existing Charles M. Schulz Sonoma County Airport terminal in Santa Rosa, using CLT to span between the wood and steel long-span trusses provided an elegant solution that addressed both structural and architectural needs. The use of CLT for the roof framing allows for simplified connections and reduced installation time to streamline construction.

Free-Standing CLT Conference Room with DSA Approval

Within a 24,000 square-foot, two-story new classroom building at Los Altos High School, a new 400 square-foot free-standing conference room provides a dramatic aesthetic impact. It was designed using CLT panels for the lid and two side walls and has been approved by the Division of the State Architect (DSA), a notoriously stringent jurisdiction that oversees K-14 projects in California.