Problem Statement

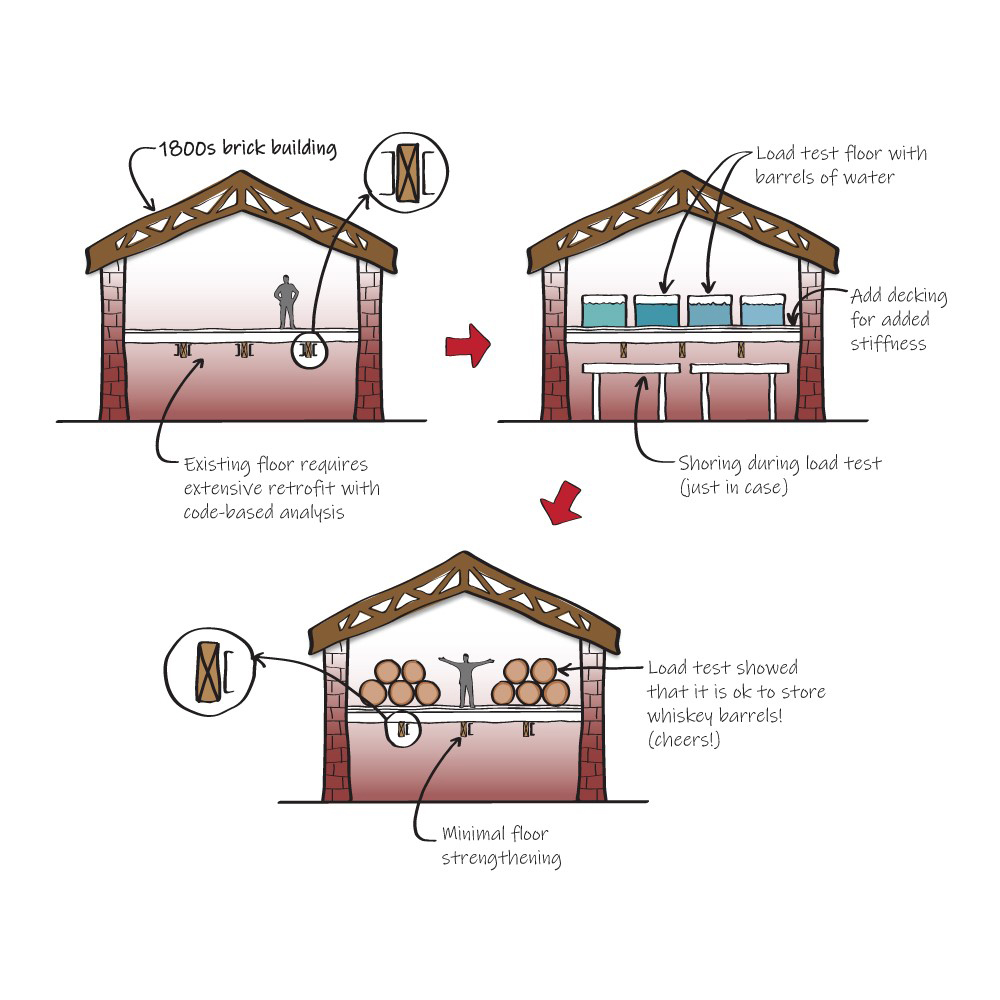

As part of the revitalization of the former Naval base at Mare Island in Vallejo, Building 45, a historic brick and wood building constructed in 1864, was repurposed as a whiskey tasting and barrel storage facility for a new distillery. The client wanted to stack two layers of 600-pound barrels on the second floor of the building, which was framed with exposed century-old wood joists, girders, and columns. The existing wood framing was analyzed and had insufficient capacity for the new loading. Based on building code provisions that included conservative values for the strength of the existing wood framing, the floor framing required new steel framing on both sides of each wood girder to resist the new loads. However, knowing that the strength of the historic wood likely far exceeded the conservative code minimums, ZFA set out to prove the strength of the existing framing to minimize the strengthening required and better preserve the beauty of the original exposed wood framing.

How ZFA Added Value

The owner made it clear early on that they very much wanted to preserve the aesthetic of the existing exposed wood framing, at least as viewed from the entry of the building. With this as a high priority, ZFA sought to utilize the full strength of the existing floor while providing strengthening as efficiently—and non-invasively—as possible.

First, the existing system was strengthened from above. To more evenly distribute the large barrel loads across multiple joists, a composite floor was designed. The composite floor consisted of existing 2x tongue-and-groove flooring with plywood on top. New 2x tongue-and-groove flooring was added on top of the existing flooring to provide a stiffer composite floor that engaged more floor joists under the new loading. Heavy timber girders were strengthened with a steel channel on one side to increase their capacity but preserve the exposed wood look on the opposite side.

To take advantage of the strength of the new steel channels, ZFA proposed an alternate installation method that would engage more of the channel capacity than a typical installation. The wood girders were first jacked up to a zero-deflection state, and, while in this position, longitudinal splits were reinforced with bolts installed vertically through the girders, compressing any delaminated areas back together. Then the single channel was installed on one side of the girders. The system was then loaded to remove any slack that occurred during installation and then unloaded. This preloading process ensured that, once the system was loaded with full barrel and live loads, the wood girder and steel channel would act together as intended. The next step was to test the strength of the composite wood-channel girder.

Historic wood is typically stronger than current design values, so although the single channel was not enough strengthening by analysis, the existing wood strength of the girder was presumed to be higher than the current design values. To verify this, the floor was proof loaded to twice the expected load for 24 hours using large containers filled with water. Testing was performed in the three worst-case locations, and the structure was monitored during testing to ensure no failures occurred. The girders passed the load test by meeting both the maximum deflection criteria under the proof load and the maximum residual deflection criteria after unloading.

The Result

By providing an alternate approach to strengthening and verification of the girder design, ZFA was able to reduce the amount of steel added to a historic structure to maintain the visual appeal of the existing wood. ZFA worked closely with the contractor to ensure a safe approach to the proof loading, and with successful testing, the client and ZFA are pleased with both the aesthetics and the load capacity of the strengthened structure.